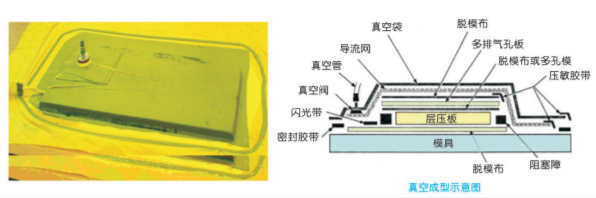

真空导入工(gōng)艺(Vacuum infusion process),简称VIP,在模具(jù)上铺增强材料(玻璃纤维,碳纤维,夹心材料等,有(yǒu)别于真空袋工(gōng)艺),然后铺真空袋,并抽出體(tǐ)系中(zhōng)的真空,在模具(jù)型腔中(zhōng)形成一个负压,利用(yòng)真空产(chǎn)生的压力吧不饱和树脂通过预铺的管路压纤维层中(zhōng),让树脂浸润增强材料最后充满整个模具(jù),制品固化后,揭去真空袋材料,从模具(jù)上得到所需的制品。真空导入工(gōng)艺公(gōng)诸于世很(hěn)久了,这个工(gōng)艺在由于这种工(gōng)艺是从國(guó)外引入,所以在命名(míng)上有(yǒu)多(duō)种称呼,真空导入,真空灌注,真空注射。

相关产(chǎn)品:多(duō)轴向,缝编毡,短切毡,表面毡

During vacuum infusion process (referred to as VIP), reinforced materials (such as fiberglass, carbon fiber and sandwich materials, different from vacuum bag process) shall be applied on moulds and vacuum bag shall be applied and vacuum shall be pumped to form negative pressure within the mould cavity. Pressure generated from vacuum shall be employed to compress the unsaturated resin into the fiber layer via the pre-applied pipe and resin impregnated reinforced materials shall fill the whole mould. After the product is cured, vacuum bag materials shall be ripped off and required product can be obtained from the mould. vacuum infusion process became known to the world long time ago. Since it is introduced from abroad, it has many other names such as vacuum infusion, vacuum irrigation and vacuum injection.

Related products: multi-axial fabric, stitched mat, chopped mat and surfacing mat